All photos by the author.

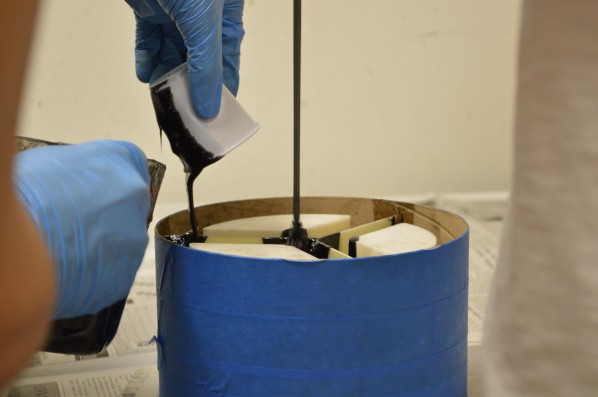

“This is rocket science,” Peter Ojdrovic said as he tried in vain to wipe the shiny black goop off his fingers and into the crevices of a mold where the stuff would harden into solid rocket fuel.

“If you go to NASA, there will be guys doing this.”

As the College of Engineering freshman stands in the corner of a fluorescent laboratory in the basement of the Photonics Building, his comment is part remark, part explanation for the situational chaos before us.

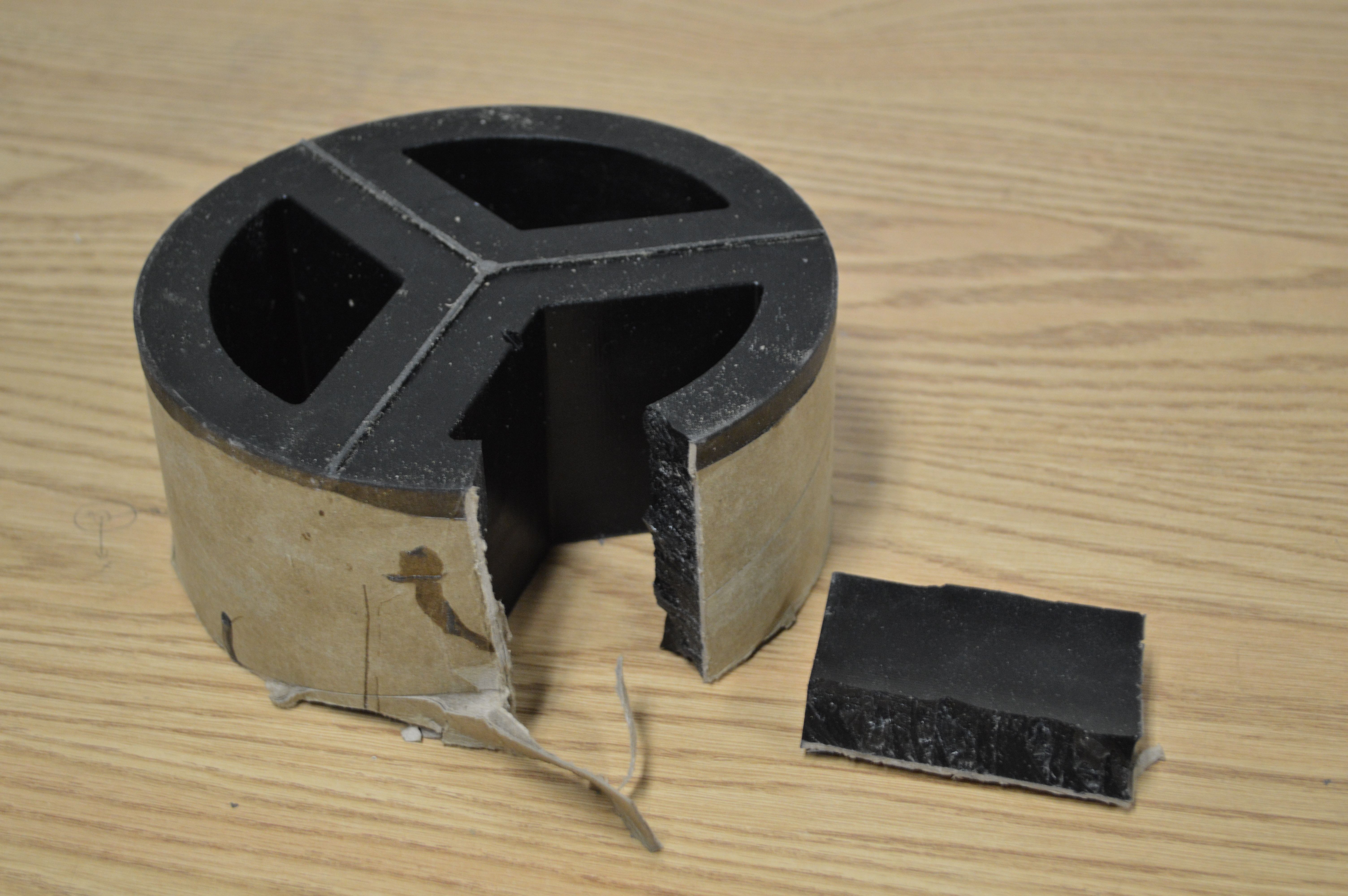

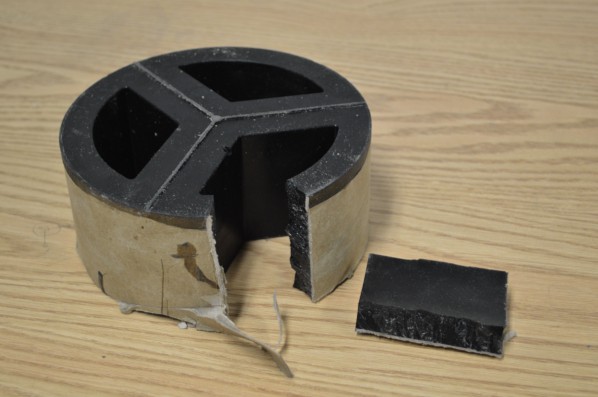

But it’d be a mistake to think he and the other members of BU’s Rocket Propulsion Group don’t know what they’re doing. When the goop sets, it will be one of four pieces that make up the fuel grain, the solid fuel in the group’s hybrid fuel rocket.

The rocket was designed entirely by the group’s director, a junior engineering student named Armor Harris, and if all goes to plan the group will launch that rocket to upwards of 100,000 feet this summer, more than double the peak height of most commercial flights.

What Ojdrovic’s comment doesn’t give credit to is the weeks he spent fiddling with techniques and chemical ratios to perfect the process they use to make the fuel grain. He did that just a few weeks after he walked into the rocket lab knowing nothing about rockets.

In the group’s rush to get their rocket ready for the last test before it’s ready to launch, they’ve been making fuel grain pretty much every day of the week. Last week, I got the chance to hang around while Ojdrovic, Harris, and a few other members of the group made a section of fuel grain. (Scroll down for photos.)

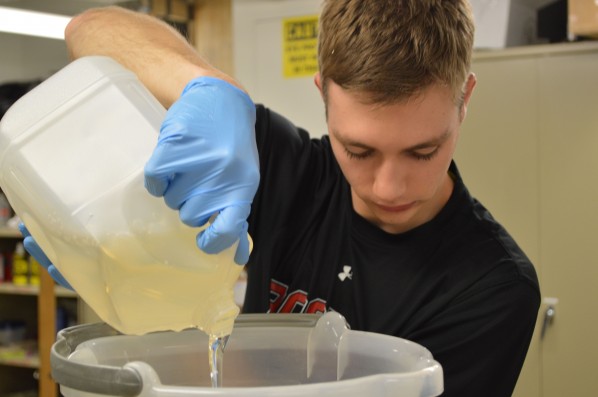

Before the fuel grain is black goop, it’s yellowish goop. In fact, the main ingredient of the fuel grain is a corn syrupy chemical called HTPB. Of course, when I say it looks like corn syrup, Harris explains that it’s actually closer to tire rubber.

They mix the HTPB with another chemical that, on a molecular level, Harris said locks with the HTPB “almost like a lattice” and will cause it to set into a hard rubber. Finally, they add some ground-up carbon to make the final product black, so it will absorb more energy, and use something like a giant eggbeater to mix everything together.

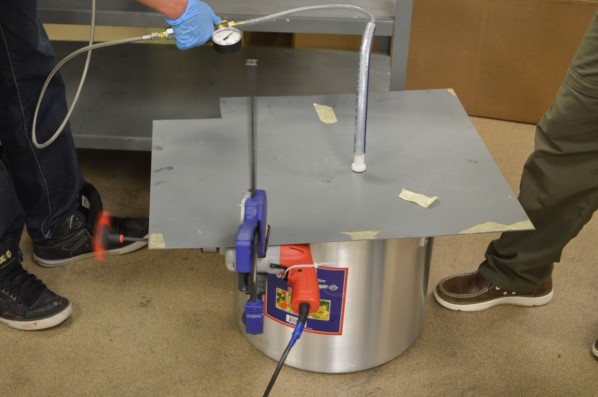

That mixing puts air into the mixture, which they don’t want because it makes the fuel less efficient, so the next step is to get that air out. To do that, they take a two-pronged approach. First, they put the bucket with the HTPB into a larger pot, which they seal with a big metal sheet and vacuum the air out of. Then, they clamp an electric drill to that sheet and turn it on to shake the mixture.

This is where things got messy.

It was the first time they’d used the larger pot as a sort of vacuum chamber, and between the vacuum and the shaking, a fair amount of the mixture had spilled all inside the pot. They had to save enough of it to fill a whole fuel grain mold, otherwise the whole process would be for nothing and they would end up behind schedule.

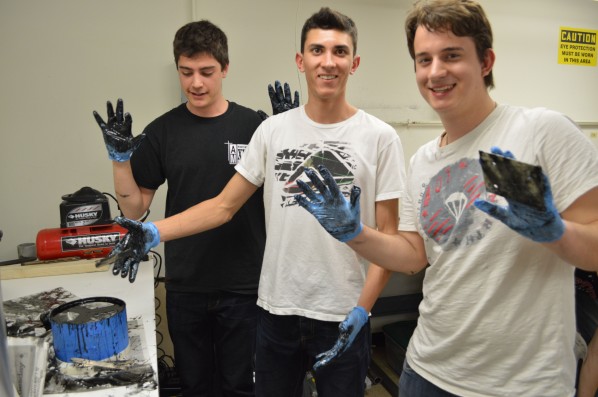

Thus, Ojdrovic and three other members of the group put on gloves and used everything they could find to scrape, pour, and wipe enough of the sticky mess from the various surfaces it spilled onto to fill the mold.

Even in a field as complex as rocket science, there’s still dirty work.